The use of portland cement in all kinds of construction was fairly new to America in the early 1900s. Previously, a mixture of sand, gravel and burned lime was used for mortar between stone and blocks. With the advent of portland cement many projects were made possible.

H. G. Adams was one of the pioneers in the use of cement on the farm and ranch. Use of concrete in ranch buildings brought him state and national attention as an industry innovator. Below is an article that appeared in a cement journal.

The Cement Era: Devoted to Cement, Concrete, and Related Machinery.

Volume 10 Page 23

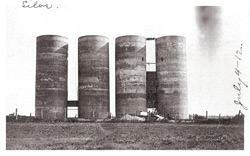

The four silos shown in this illustration are on the ranch of Horace G. Adams, Maple Hill, Kansas, and hold 2000 tons of corn and silage, having a capacity of 500 tons each. They are 60 in height and have an inside diameter of 20. The floor of each silo is 3 below the surface of the ground and the concrete walls are solid walls 6 thick.

The concrete is a 1-2-3 mixture of cement, sand and gravel. The reinforcing consists of rolled, twisted, square iron bars. In the lower 24 of the silo, the bars are 5/8 and in the upper portion thick. The openings are 20 high and 30 wide and are fitted with doors of 20 Gauge Steel, galvanized and painted.

The cost of these silos was $800 each and they were built by George A. Hopper and Sons, Manhattan, Kansas. They are built on what is known as the Polk System, controlled by Polk-Genung-Polk Company of Fort Branch, Indiana. Hopper and Sons is the Kansas representative of this company.

In the perfection of their system, Polk-Genung-Polk have kept two things in mind, namely, ease of operation and an absolutely flawless structure. No expense has been spared to allow the owner to put up as good a silo as the best mechanic can erect. The machine automatically forms the walls true to line, it does away with an elaborate system of scaffolding, there is no strain upon the section of the wall already built, and it so unifies and simplifies the work that any intelligent man, after seeing one silo constructed, can easily erect one for himself.

Here in given is a line sketch of this machine. As can be seen, the entire load is carried on the 4 steel center mast. This mast is erected carefully at the center of the foundation and is carefully plumbed. Upon it, the form bearing part of the machine works, guaranteeing a structure of absolutely perfect alignment because of the ease of plumbing the mast. Over this steel mast works a slideable hub. This hub is also a steel pipe of larger diameter carrying the radial tee irons and larger rods, which, combined carry the forms proper. The entire machine is made of sheet and structural steel, and is sturdily designed and heavily built. It will stand wear indefinitely if not abused. J

The system of assembling and taking down machines is developed to the point of complete simplicity, only a few wrenches being required to accomplish the operation. The forms proper are made of cold, rolled, steel and are perfect arcs of circles. Special scrapers for keeping the sections clean are furnished with each machine. Different diametered forms may be used on the same spider, giving a latitude for varying conditions. With the exception of a few bolts and hoisting, the whole mechanism can go through a season without a penny for repairs.

The photograph below is of the four huge concrete silos built on the H. G. Adams Headquarter Ranch at Maple Hill.